Portfolio Details

- Categories Maneuvers

- Tags EM2000, EM2000 V5.1, HANDLER PLATE, MANEUVER

- CountryCanada

Description

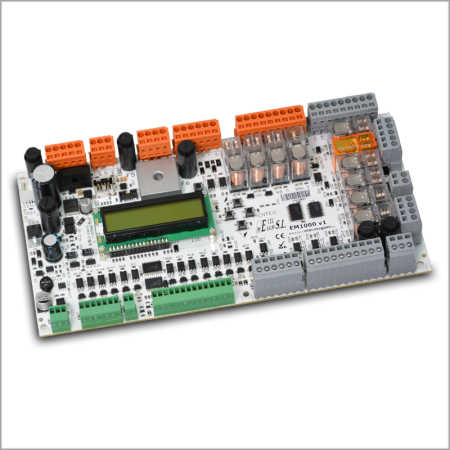

- The evolution of the original EM2000 controller with a long trajectory of 10 years and more than 20,000 installed operations, due to this experience, together with the needs of our customers, the new regulations, the characteristics that distinguished our previous model, the proven reliability and fundamentally the desire to improve, have been reflected in the new EM2000 V5.1 controller.

- The technical team, together with all Elecmegom’s staff, has been involved in the development of this new maneuver, in order to achieve a unique, reliable, easy to install and, what seems to us even more important, simple to maintain product.

- Design based on a single-plate maneuver, which can be compatible with all types of existing lifting systems, 1 or 2-speed electric, hydraulic or VVVF control either in its asynchronous motor version or gearless permanent magnet synchronous.

- Board optimized for elevator control, including features such as battery charger, system control for A3 compliance, parameter setting directly on the control board, inspection maneuver on the board itself. integrated machine room temperature control, emergency siren output and with the same loudspeaker output for the GONG output on arrival at the plant.

Maneuver |

EM2000 V5.1 |

||

| Type | Universal | Selective | Collective Up/Down |

| Coordinates | 24 | 24 | 14 |

| Multiplex maneuvers | Up to four elevators operating in multiplex | ||

| Types of traction |

|

||

| No machine room | Synchronous and asynchronous motors

Integral cabinets, including the frequency converter Divided cabinets, control at landing and inverter in shaft |

||

| Speed | Up to 1.6 m/sec. | ||

| Emergency rescue |

|

||

| Telemaintenance | Compatible with the megom OnLine platform via the Internet. | ||

| Regulations |

|

||

| Standards A3UNE-EN 81-2:2001 + A3:2010UNE-EN 81-1:2001 + A3:2010 | Compatible with the following systems

|

||

| Emergency system | Includes emergency system

|

||

| Call log | Outputs for outdoor registers 24Vdc positive common individually protected against short-circuit. | ||

| Tickets |

|

||

| Auxiliary outlets |

|

||

| Button panel signaling | Multivoltage Outputs

Outputs 24Vdc

|

||

| Inspection from the EM2000 board | Normal/inspection switch

Up pushbutton Down pushbutton |

||

| EM2000 on-board help buttons | One pushbutton for each cabin and outside calls

Door reopening button NVI leveler test button NVP Leveler test button Siren button * All pushbuttons with an associated LED |

||

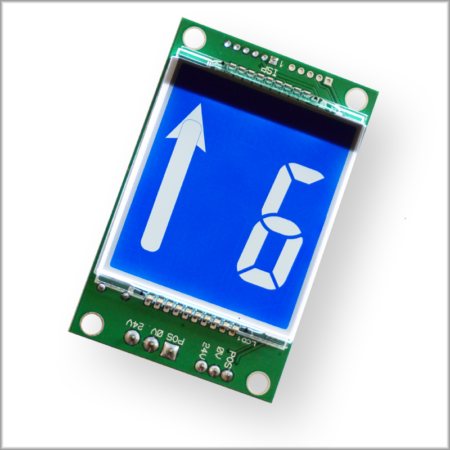

| Programming | Using the inspection buttons on the board and theLCD call buttons included on the control board | ||

| Plant indicators | Single-wire control of

|

||

| Door operator control |

|

||

Technical specifications EM2000 maneuver |

|

| Board supply voltage range | 18Vac / 24Vac |

| Safety series voltage range | 110Vac / 130Vac |

| Lighting control input voltage range | 200Vac / 250Vac |

| Emergency ceiling outlet voltage | 12Vdc (1A) |

| Auxiliary output voltage for other elements | 24Vdc (3A) |

| Emergency auxiliary output voltage for other elements | 12Vdc (1A) |

| Tension of call records | 24Vdc positive common (protected against short circuit) |

| Voltage of luminous outputs | Any AC or DC voltage

4 Amps per output Rising light Light lowered Open door Busy |

| Communications ports |

|

| Mechanical dimensions EM2000 plate | Width 200mm x Height 270mm x Depth 50mm. |

| Type of connections | Plug-in clamp-type connectors (Wago) |

| LCD message display | 16-digit two-row green LCD |

| Potentiometers | Door opening time (3 to 14sec.)

Waiting time between calls (3 to 15sec.) Arrival GONG volume |

| Configuration switches | SW1 – 8 switch of maneuver configuration

SW2 – 8 switch configuration switch

SW3 – 2 siren tone selection switch SW4 – 2 GONG tone selection switches |

Configurable parameters EM2000 V5.1 maneuvering |

|

| Programming system | By means of the inspection pushbuttons on the plate and call buttons

LCD 2*16 included on the control board |

| Access to configuration | With configurable 4-digit password |

| Troubleshooting menu | Last 32 failures with the following data for each of them

Fault numberFault code Floor where the elevator was located Direction of travel or state of rest Speed at which it was operating Reset of the entire fault stack |

| Parameter programming menu |

|

| Parameter initialization | Initializes Display codes

Initializes floor doors Initialize floor magnetsFull initialization (default parameters) |

Optional equipment for EM2000 maneuvering |

|

| Multiplex Plate | EM2MUL up to 4 elevators |

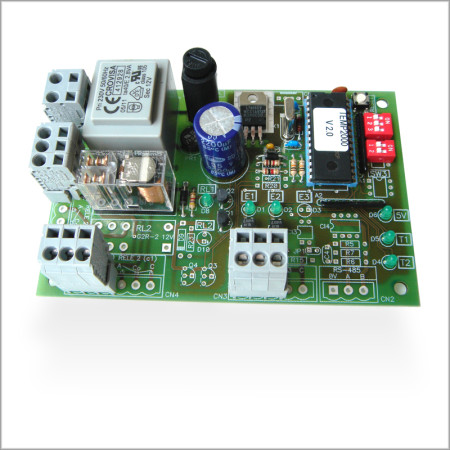

| Hydraulic power plate | EM2HR for hydraulic maneuvering |

| Asynchronous VVVF power board | EM2VFR for geared motors |

| VVVF gearless power board | EM2VFF for permanent magnet motors |

| Multiplex calls up to 16 | EM3ADA (Parallel calls up to 16 stops) |

| Multiplex calls up to 24 | EM2COM28 (Parallel calls up to 24 calls) |

| Inspection pushbutton panel plate | EM2PBR3 interconnection board in pushbutton panel |

| Inspection pushbutton panel | METALIC inspection pendant adapted to EM2000 control system |

| Voice synthesizer | EM2PRO Multi-language voice synthesizer* Synthesis is included in the EMBI_Eco or EMBI_v4 modules. |

| Brake/lever/valve rectifier | EMRECT rectifier up to 3A, EMRECT12 rectifier up to 12A |

| Communication systems |

|

| Compatible positionals |

|

| Load control systems | VK3 Load Weigher

Load cells with integrated load cell in LCK cables |

| Voice synthesizer | EM2PRO Multi-language voice synthesizer* Synthesis is included in the EMBI_Eco or EMBI_v4 modules. |

| Compatible frequency inverters | Maneuvers for geared machines

Maneuvers for gearless permanent magnet machines

|

For users of this product we provide a complete guide in different languages. Click on the flag icon corresponding to the language you wish to download.