Portfolio Details

- Categories Maneuvers

- Tags ADAPTATION, EMADA, VARIATOR

- CountryCanada

Description

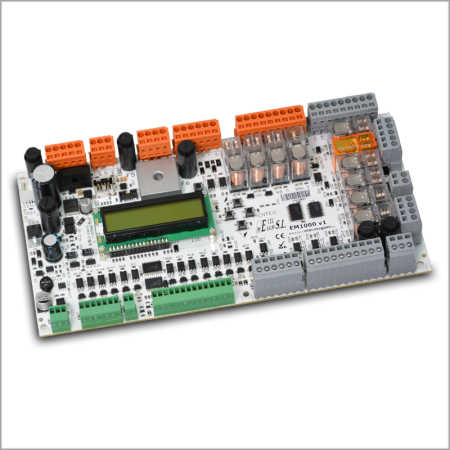

- As a solution to the great demand received to update existing controllers, regardless of the manufacturer, which before the adaptation work in one or two speeds, and which need a frequency converter control, with which is achieved in addition to a precise stop, a comfort that can not give a motor controlled by a conventional system, under normal conditions would be forced to replace the entire controller, Elecmegom has successfully developed the EMADA adaptation and has been marketing since 2013.

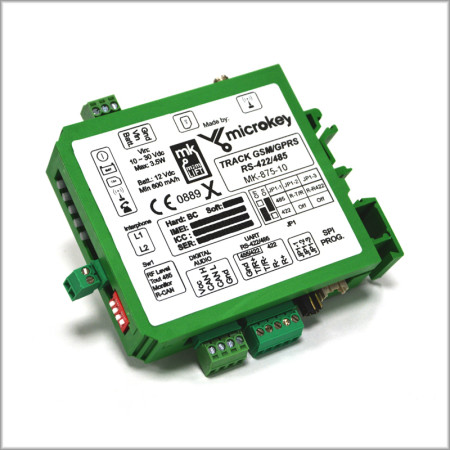

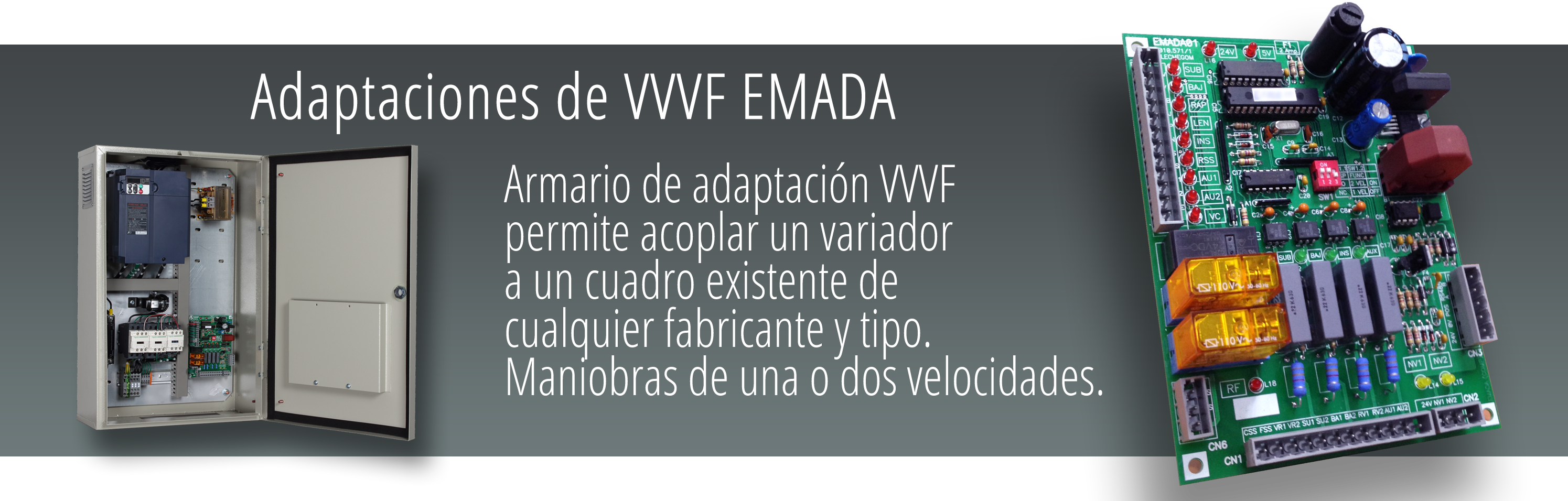

- It consists of a small cabinet with a frequency inverter, which is installed next to the existing one, with minimal interconnections between the two cabinets, it is achieved that the old controller gives us the necessary information to govern the inverter with all the features that a conventional controller would do, but reducing its cost by 50% over the current value of any controller on the market.

- Its main feature is the ease with which the installation is done, intuitive and with virtually no need to modify the main cabinet, this feature along with the simple implementation of the drive, makes it an alternative to consider in communities where you can take advantage of the existing cabinet and you want to give a plus both comfort and economic improvement in the reform of the elevator.

- The frequency inverter adds durability to the mechanical parts that make up the traction system, the machine itself, the brake, the traction cables, etc., by achieving smooth accelerations and decelerations, avoiding jerks and sudden stops that cause greater wear of mechanical parts and therefore a premature change compared to systems that integrate the frequency inverter.

- Safe control system, subject to the elevator safety series, it will never make any movement if these are not closed, in case of a series fall while the elevator is working, the EMADA adaptation will stop immediately in a safe way.

- In the case of a 2-speed control it is not necessary to include any position control element, since the adaptation board will work with the same signals as the control currently does, in 1-speed control, only a magnetic detector will be necessary for the plant level control.

- So far, all of the shunts without exception, to which an EMADA has been installed, are working properly, and customers have been fully satisfied with the result, the experiences have been multiple, with different brands and models of shunts, in all cases the solution was present in the design of our EMADA adaptation circuit.

- It performs brake control, thus achieving better synchronization between the variator and the motor, resulting in smooth starts and progressive decelerations, performing millimetric leveling on the ground.

- In addition, it controls the opening of doors, so as not to allow their opening until the elevator is completely stopped.

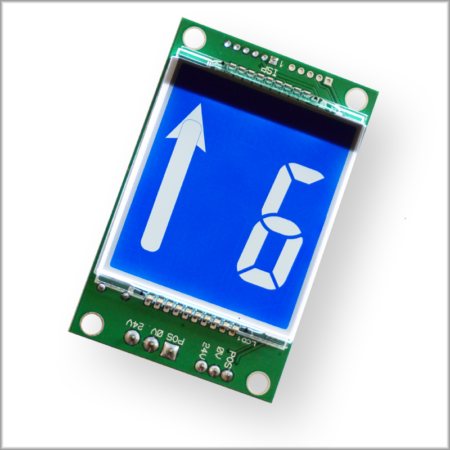

- Another of its outstanding features is that it can control without the need to add additional elements, floor positional and graphic displays to be placed in the cabin or on the floor landing, it can also control a voice synthesizer to inform in the cabin through voiceovers of the floor to which the elevator arrives.

Maneuver |

EMADA (Adaptation to any maneuver) |

| Types of traction |

|

| Maneuver models | Any manufacturer and model |

| Coordinates | Any number of stops |

| Engine type | Asynchronous motors with gearboxes |

| Speed | Up to 1.2 m/sec. |

| Telemaintenance | It is not compatible with the megom OnLine platform. |

| Regulations |

|

| Tickets |

|

| Thermistor input |

|

| Inspection entry |

|

| Control outputs |

|

| Programming | Operation programming switches |

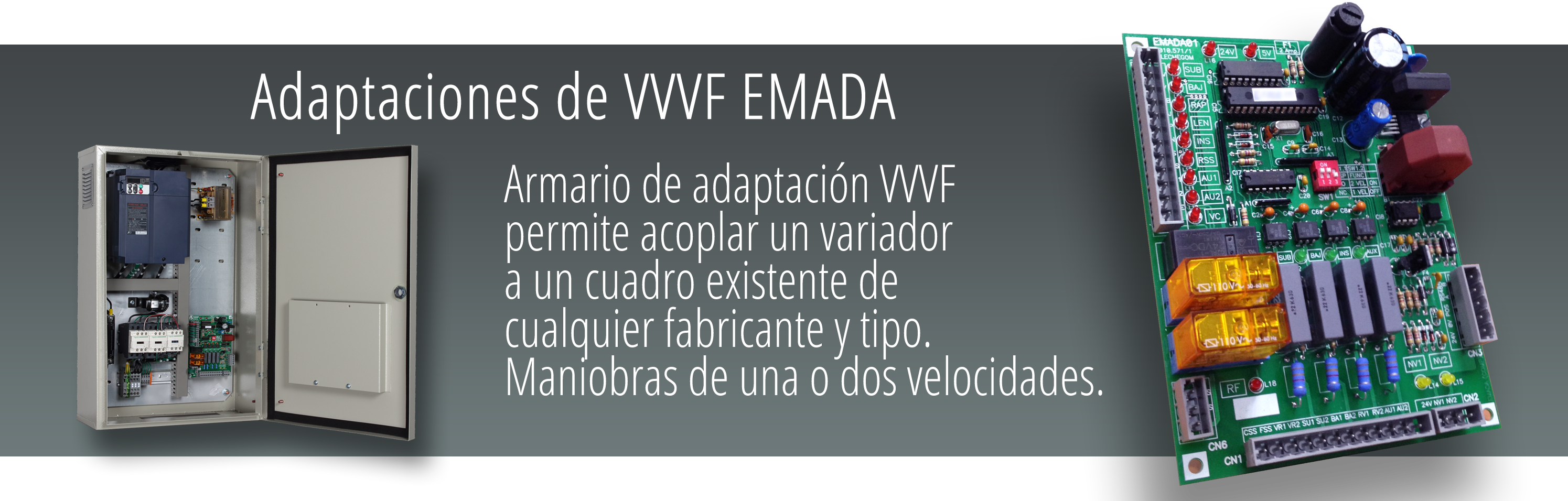

| Signal indicators | Signaling of inputs and outputs by means of LEDs

|

| Door control |

|

| 1-wire communication |

|

| 2-wire communication |

|

Technical specifications adaptation to EMADA maneuvers |

|

| Board supply voltage range | 18Vac / 24Vac |

| Safety series voltage range | 24Vac-Vdc / 230Vac-Vdc |

| Output voltage of general contactors | 24Vac-Vdc / 230Vac-Vdc (5A) |

| Brake contactor output voltage | 24Vac-Vdc / 230Vac-Vdc (5A) |

| Auxiliary output voltage for other elements | 24Vdc (3A) |

| Communications ports |

|

| Mechanical dimensions EMADA plate | Width 117mm x Height 155mm |

| Mechanical dimensions EMADA cabinet | Width 425mm x Height 650mm x Depth 250mm |

| Powers in Fuji Multi |

|

| Included variator elements |

|

| Type of connections | Plug-in clamp-type connectors (Wago) |

Configurable parameters in EMADA maneuver |

|

| Programming system | By means of 3 programming switches

|

| internal programming | Sequence of stops for non-graphical plant positionals

Sequence of stops for graphic displays Synthesizer floor sequence |

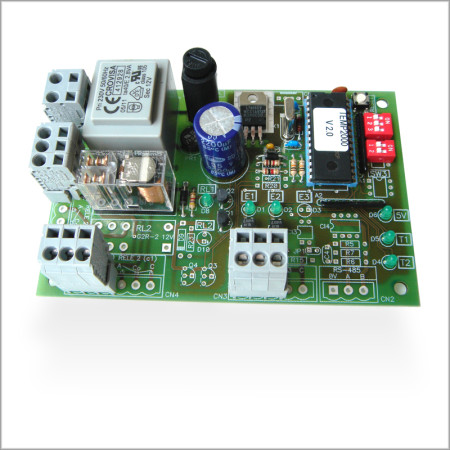

Optional equipment EMADA maneuver adaptation |

|

| Compatible positionals |

|

| Voice synthesizer | EM2PRO Speech synthesizer multiple languages

EMBI_v4 Bidirectional communication module with Track |

| Compatible frequency inverters | Maneuvers for geared machines

|